|

TZM

11 Engineering Office Ltd.   |

| Works |

Centrifugal feeder |

Hydraulics |

HELP |

Partners,

favourites |

Home |

| Gasco

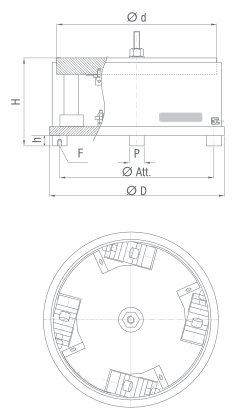

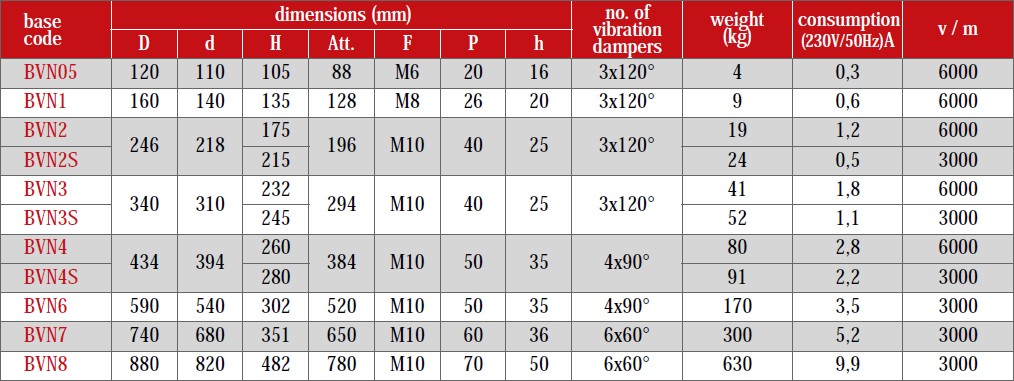

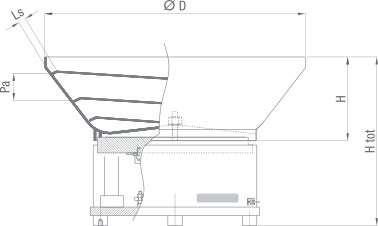

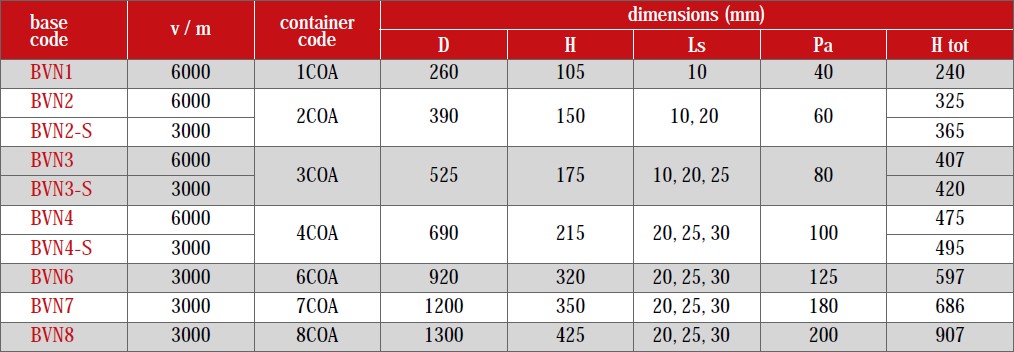

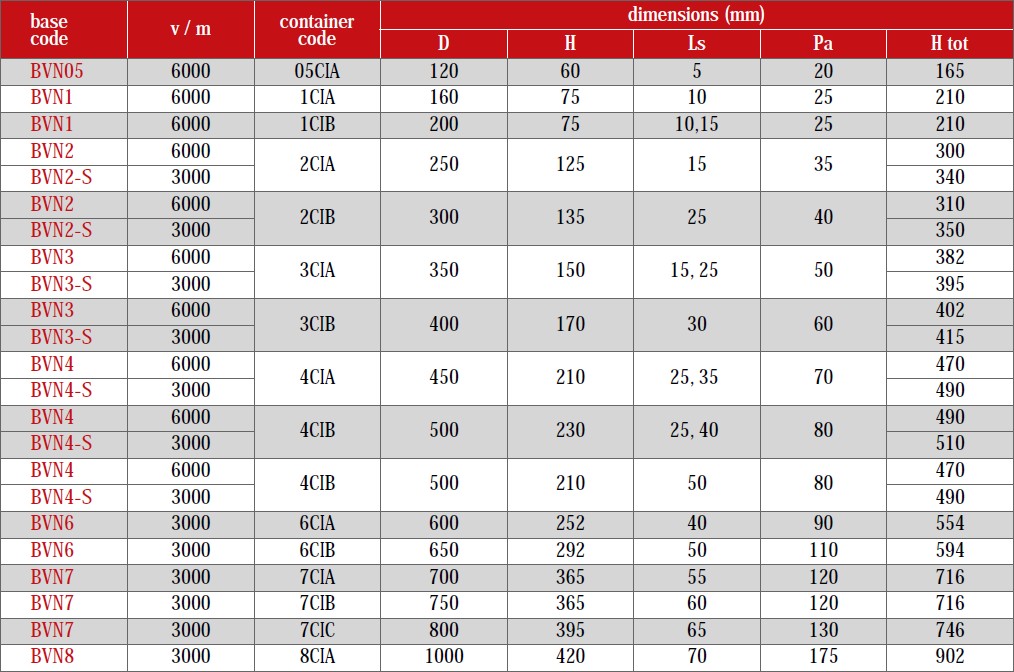

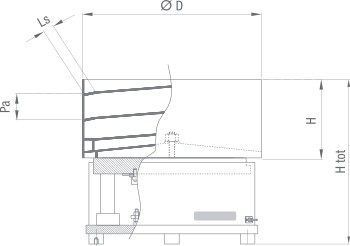

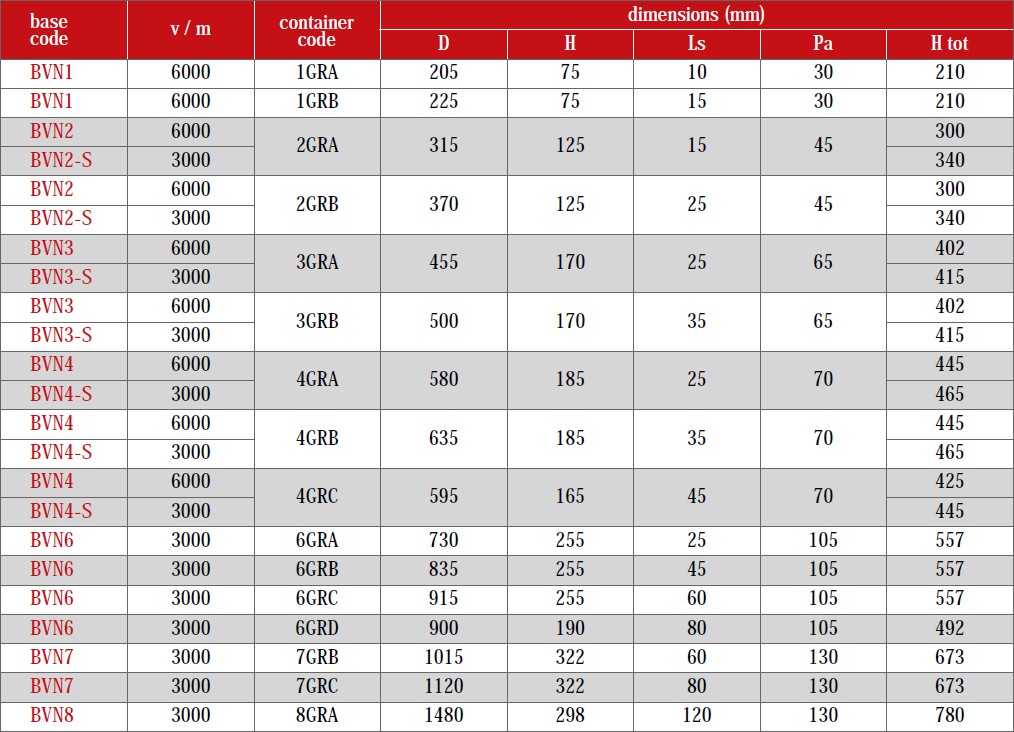

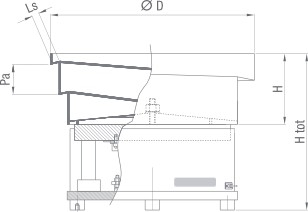

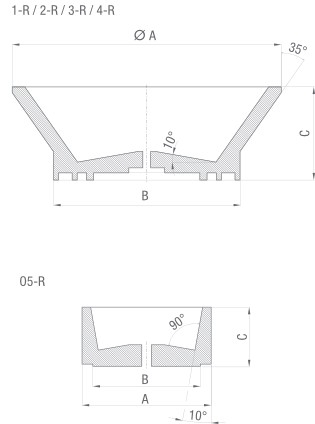

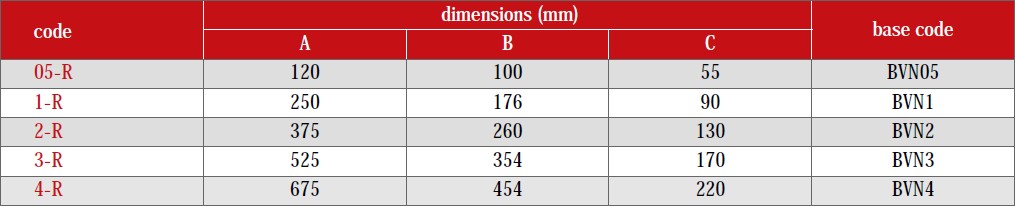

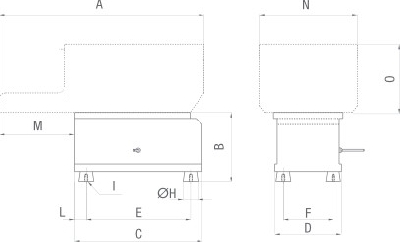

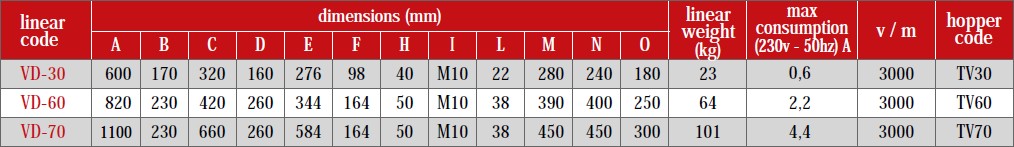

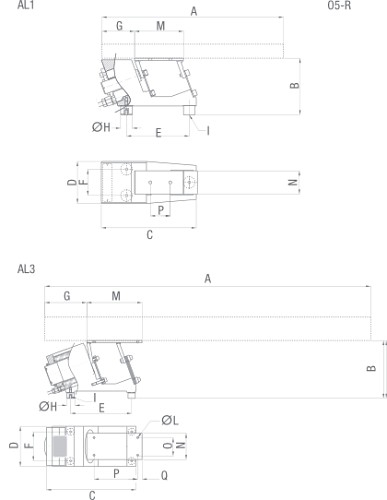

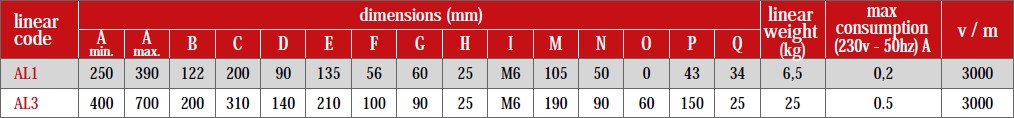

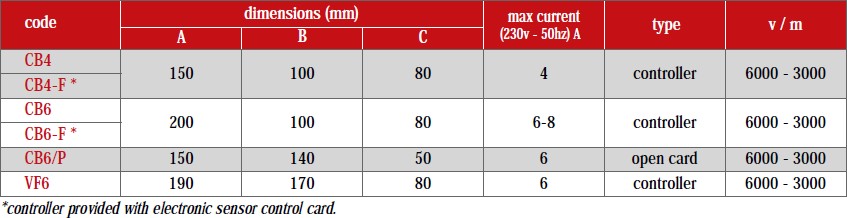

vibratory feeders We suggest the following products into Your kind attention as hungarian reseller of italian GASCO group s.r.l. firm. Of course, if needed we can deliver ready to use full-scale component feeding solutions, requiring: - Sufficient sample giving (typically a minimum replenishment cycle is sufficient) - Product drawing (because of the dimensions and tolerances) - Orientation of the dispensed piece at output - Dimensioned sketch geometry (installation, installation environment) - Output spatial position (from vibratory feeder) - Feeding capacity pieces / min - Required components charging time 5-10-20 minutes, 1 hour, etc. - Additional information about feeding components, such as cleanliness (oil, dust, etc.), finishing, vulnerability, etc. - Additional information about feeder device(s) such as color, noise, clean room, food HACCP, pharmaceutical sterilization requirements, etc. Of course we are at Your service also for the total solution as special purpose machine designing and manufacturing. Vibrating bases The vibrating bases on which the containers are fixed represent the motor of the system. The vibrating bases supplied by the Gasco group are distinguished by their above average level of reliability and safety, even after extended use over time and continuous, stressful production cycles. The use of high efficiency electromagnets and leaf springs enables high transport capacity that is independent of the parts loaded in the circular container. The wide range of models, from diam. 100 to diam. 820, enable reliable use for each container type and size. The only one in Europe, our base BVN8 diam. 820, makes it possible to use large capacity containers (cylindrical diam. 1000; cone-shaped diam. 1300; stepped diam 1500) and therefore the possibility to orientate large sized pieces. The supply voltage is 230V/50Hz single-phase. They require an electronic controller (see controllers). Upon request, they can be supplied with different voltages and frequencies.   Downloadable 3D modells are on the Gasco's website. CONE-SHAPED CONTAINERS When defining the structure of the standard container to use, the structure of the part to orient and the type of selection to be made must be kept in mind. Our standard models are built in AISI 304 stainless steel. In relation to the special needs of the product to orient, containers can be implemented with different dimensions (external diameter, coil and pitch width) and different materials (AISI 316 stainless steel, manganese steel, resin, etc.) or coated with wear-resistant, sound-resistant and oil-proof materials. In general, the cone-shaped container has a good filling capacity and makes it easy to pre-select the part to orient. Recommended for thin and round pieces (washers, o-rings etc.) it comes standard with a dish at the bottom that positions the pieces against the wall. All models are made using specific moulds, using the spin forming technique, which permits optimal rigidity and geometric form. Special productions possible with dual or multiple way tracks.   Downloadable 3D modells are on the Gasco's website. CYLINDRICAL CONTAINER In general a cylindrical container makes it possible to have a diameter that is smaller than the vibrating base and therefore the use of external selectors that return to the bottom, suitable for pieces with complex structures at a high speed. This advantage is opposed by a limited filling capacity, which can be easily resolved by using an automatic loading system (hoppers, vibrating tanks, vertical loaders, etc.). Special productions possible with dual or multiple way tracks or coils.   Downloadable 3D modells are on the Gasco's website. STEPPED CONTAINER A stepped container provides an elevated filling volume, preventing the pieces from becoming stuck between the spiral tracks. In addition, precisely due to the containerís form, it makes faster feed speeds possible than with cylindrical and cone-shaped containers. Special productions are possible with a sloping track toward the inside of the container, for the selection or particular pieces.   Downloadable 3D modells are on the Gasco's website. RESIN CONTAINER The characteristics of resin containers are favourable for piece sliding and feeding. Due to a dedicated project design and the use of suitable machine tools, this container can be configured in a flexible and reproducible manner. The form of the container and the one or two way spiral can be created based on the piece to orient. Also the high speeds that can be obtained must be considered in addition to a significant reduction in the noise level.   RECTILINE The rectilinear feeders are driven by an electromagnet that feeds the pieces oriented inside the linear channel installed above the vibrating feeder. Generally used to connect the point where the piece exits the circular guide with the automatic machine press and handling station, it also acts as a storage unit, guaranteeing a continuous and regular feed. Supply voltage 230V/50Hz single phase. They require an electronic controller (see controllers). Upon request, they can also be supplied with different voltages and frequencies.   Downloadable 3D modells are on the Gasco's website. VD MODEL LINEAR FEEDERS The VD model rectilinear vibrating feeders are used in dosing and transporting different types of bulk products (fruit and vegetables, foodstuffs, mechanics, plastics, etc.). They are generally used in weighing and packaging sectors in combination with single or multi-head scales and require an electronic controller that makes it possible to vary the delivery capacity also during operation (manually or with the PLC). The VD models are particularly suitable for transporting entangled parts that get stuck easily using vibrating hoppers with a variable capacity based on the pieces to be transported. The tray-type vibrating hoppers used together with the linear vibrating model (VD) are available with variable loading capacities and, upon request, with different dimensions and volumes. They are provided with an adjustable gate, which enables outlet dosage. Upon request, they can be supplied with supports or support benches and with an internal polyurethane coating. Supply voltage 230V/50Hz single phase. They require an electronic controller (see controllers).   Downloadable 3D modells are on the Gasco's website. AL MODEL LINEAR FEEDERS The AL model vibrating linear feeders are used in dosing and transporting different types of bulk products (fruit and vegetables, foodstuffs, mechanics, plastics, etc.). They are generally used in weighing and packaging sectors in combination with single or multi-head scales, require an electric controller, with which it is possible to vary the delivery capacity also during operation (manually or with the PLC). The hopper channels, which are installed above the vibrating feeders, are available in a standard and special version, depending on the material to be transported or specific application requirements. The AL1 and AL3 models are especially suited when a significant front protuberance is required due to dimension or measurement requirements and to feed the fixed hoppers. Supply voltage 230V/50Hz single phase. They require an electronic controller (see controllers).   Downloadable 3D modells are on the Gasco's website. CONTROLLER AND ELECTRIC PANELS FIXED FREQUENCY CIRCUITS These are stabilised circuits that were specifically designed to regulate the vibration amplitude of the vibrating devices (circular or linear). They are provided with a suitable circuit for a smooth start, with the possibility to select the ramp time (0.2 sec/2 sec) and operate either at 50Hz or at 60Hz. They can be controlled manually or via a PLC. Their main features also include a wide range of extremely linear adjustment and the possibility to shut off the vibrator during normal operation, using a live or potential free on/off contact (0-24 vdc). In addition to the above described basic circuits, there are those that control the electronic sensors PNP/NPN, which can manage a part flow failure with a relative alarm. VARIABLE FREQUENCY CIRCUITS These are used to optimise vibrator operation, searching for its resonance frequency and eliminating a long and difficult calibration process. ELECTRIC PANELS Our product range is completed by the electric panels, which are customised for operating systems such as: PLC controlled, motorised or vibrating circular, linear, hopper systems.   Downloadable 3D modells are on the Gasco's website. |